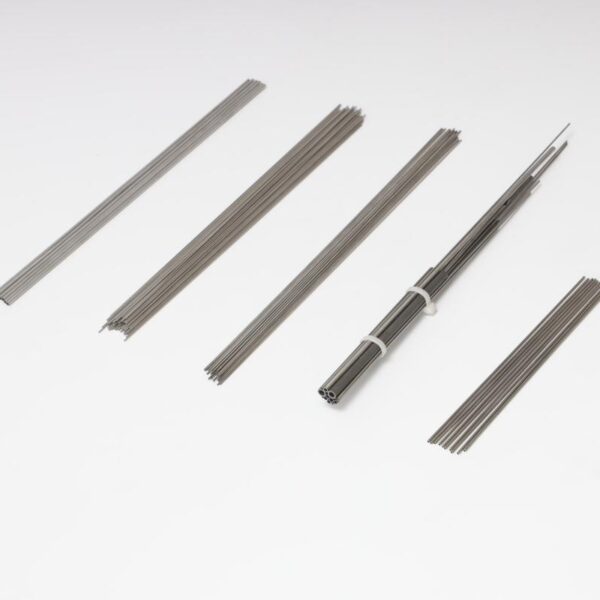

Surface state:Black oxidized state,light oxidized state(from golden yellow to brown)

Packing:I-shaped wheels:evenly distributed,without fractures or disorderly lines

Fixed length:can be cut to a fixed length according to customer needs

Applications:Orthopedic and dental instruments,spine,endoscopic manipulation,snares,net baskets

Mechanical properties

| Upper platform | Tensile | Elongation | Residual deformation | Phase transition |

| >350MPa | >1000MPa | >10% | <0.5% | -10~20℃ |

Description

Basic Information Level

Nitinol flat tubes are specialized components crafted from nickel-titanium alloys. These tubes offer unique properties like shape memory and superelasticity. Industries use them in medical devices, aerospace, and robotics. Nitinol flat tube suppliers offer a range of sizes and custom designs.The material resists corrosion and withstands extreme temperatures.

Application

Nitinol flat tubes are frequently used in medical stents and orthodontic wires. Aerospace engineers utilize them in actuators and sensors.Robotics applications are valued for their flexibility and durability. Automotive and energy sectors also rely on these tubes. Nitinol flat strip providers ensure precision for critical uses.

Comparison to Competitors

Nitinol flat tubes outperform stainless steel and titanium in flexibility. They last longer under repetitive stress than conventional metals. NiTi flat tube distributors offer better fatigue resistance solutions. Rivals find it challenging to match Nitinol’s blend of strength and elasticity. Many industries now prefer Nitinol for high-performance needs.

Technical Properties

Nitinol flat tubes exhibit superelasticity up to 8% strain. They maintain shape memory at specific temperatures. The alloy has excellent biocompatibility for medical uses. Suppliers ensure tight tolerances and consistent quality. These tubes also resist wear and chemical damage effectively.

Market & Trends

The demand for Nitinol flat tubes is increasing in minimally invasive surgery. Aerospace innovations drive the need for lightweight, durable materials. NiTi flat tube distributors report rising orders from robotics firms. Emerging markets in Asia and Europe show increased adoption. Future trends suggest more automation and medical advancements.

Accessories & Support

Leading Nitinol flat tube suppliers offer cutting and shaping services. Custom coatings enhance performance for specific applications. Technical support ensures proper integration into projects. Many providers supply testing reports and material certifications. Dependable distributors also support logistics and handle bulk orders.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Reviews

There are no reviews yet.