| Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) | Diameter(mm) | Tolerance(mm) |

| 4.000-2.000 | ±0.025 | 0.350-0.260 | ±0.010 | 0.08-0.050 | ±0.005 |

| 2.000-1.000 | ±0.020 | 0.260-0.150 | ±0.007 | 0.050-0.025 | ±0.005 |

| 1.000-0.350 | ±0.010 | 0.150-0.080 | ±0.005 | 0.025-0.018 | ±0.003 |

Description

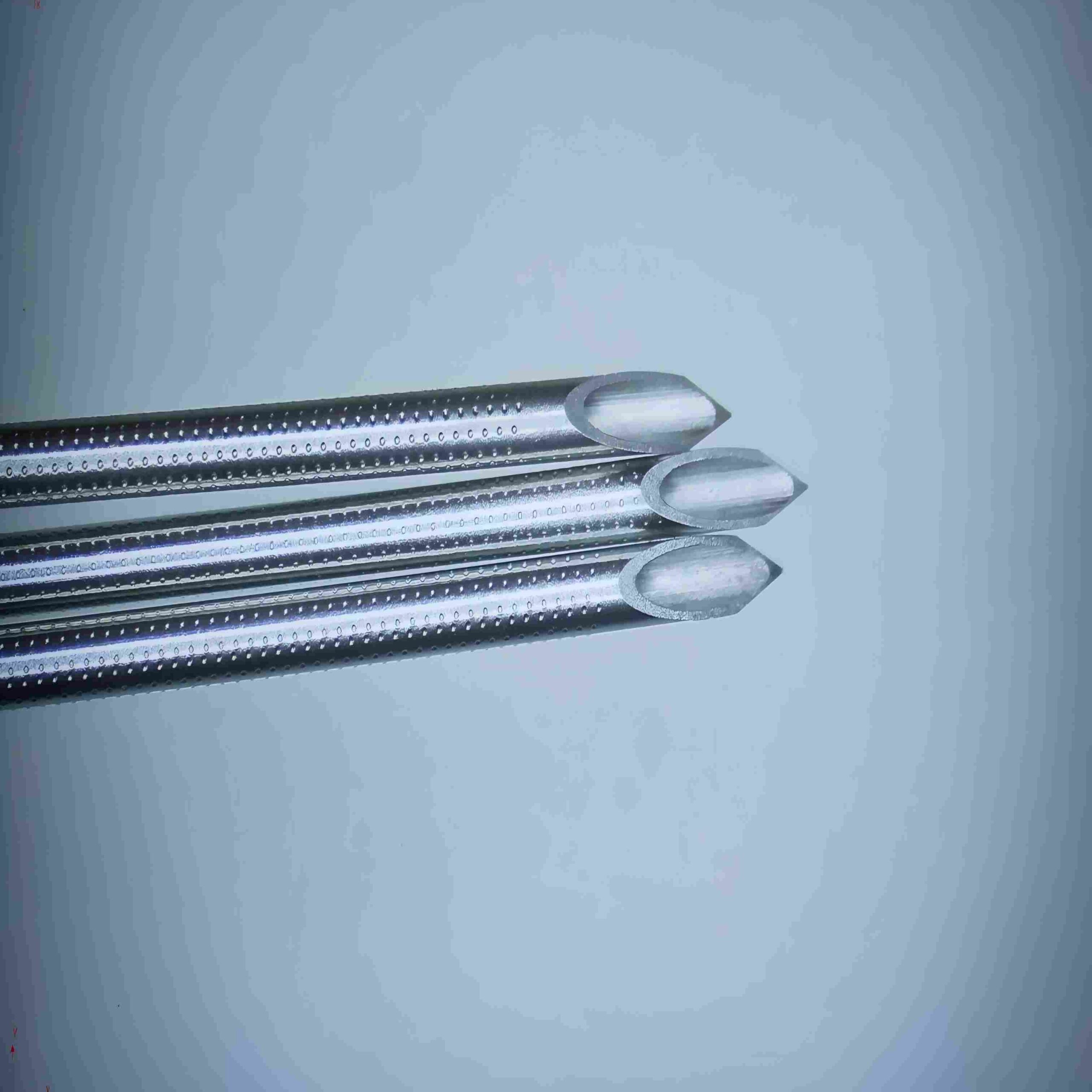

Expert Nitinol Tube Development Processing & Laser Cutting Services

Our company specializes in advanced Nitinol tube development processing, offering precision laser cutting services for medical device hypotubes. We support medical innovators with end-to-end manufacturing solutions, ensuring superior quality and performance for critical applications.

Nitinol Material Expertise

Nitinol is a unique metal alloy of nickel and titanium, known for its shape memory and superelasticity. These properties allow it to endure significant deformation and return to its original shape, making it ideal for demanding medical uses. Our Nitinol tube development processing leverages these characteristics to produce highly reliable components.

Solving Nitinol Processing Problems

Conventional machining often fails with Nitinol due to several challenges:

Material Toughness: Nitinol rapidly work-hardens, causing excessive tool wear.

Heat Sensitivity: High temperatures during processing can compromise material properties.

Springback: The material strongly resists deformation, complicating precision cutting.

Burr-Free Requirements: Medical applications demand flawless, smooth edges.

Our Nitinol tube development processing overcomes these issues with state-of-the-art fiber laser cutting. This method ensures minimal heat impact, no tool contact, and exceptional accuracy, preserving the material’s integrity and functionality.

Key Applications of Nitinol Hypotubes

Nitinol is essential for many modern medical devices, including:

Vascular stents to restore blood flow.

Flexible guidewires for navigating delicate vessels.

Orthodontic archwires that provide consistent pressure.

Tools for minimally invasive cardiac and neurological procedures.

Through advanced Nitinol tube development processing, we help create devices that save lives and enhance patient outcomes.

Nitinol Safety and Biocompatibility

Nitinol is biocompatible and safe for human contact. Regulatory agencies worldwide approve it for long-term implants. We adhere to strict cleanliness and safety standards, ensuring every component meets medical-grade requirements.

Precision Diameter Range for Hypotubes

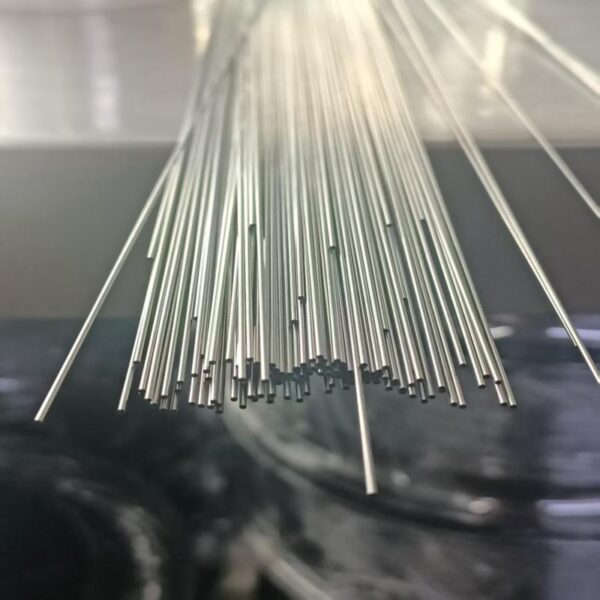

Our Nitinol tube development processing accommodates a broad spectrum of dimensions:

Outer Diameters: 0.5 mm to 5.0 mm

Wall Thicknesses: 0.05 mm to 0.5 mm

We achieve high precision and consistency across all sizes, enabling complex geometries for next-generation medical devices.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

Europe Region:nitinolmetal.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Nitinol Wire – Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Nitinol Tube – Precision-engineered tubing ideal for minimally invasive devices and high-performance systems.

Reviews

There are no reviews yet.