| Outside dimensions(in) | Wall thickness(in) | Tolerance range(in) | Length(in) |

| 0.0079 | 0.0008 | ±0.0005 | >0.0.02 |

| 0.01 | 0.001 | ±0.0005 | >0.0.02 |

| 0.011 | 0.0015 | ±0.0005 | >0.0.02 |

| 0.014 | 0.00135 | ±0.0005 | >0.0.02 |

| 0.075 | 0.0025 | ±0.0005 | >0.0.02 |

Description

Micro-Cut Nitinol Sleeve – 0.0079″ Inner Diameter × 0.063″ Outer Diameter

Product Overview

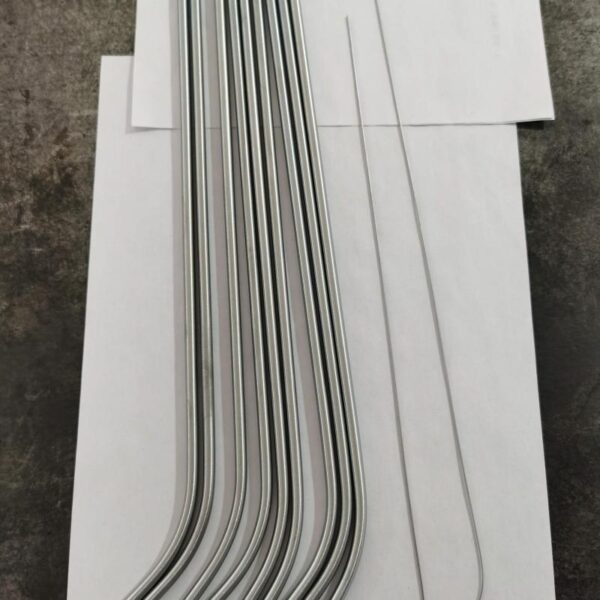

The Micro-Cut Nitinol Sleeve is a high-precision micro tubing component engineered for applications where accuracy, flexibility, and reliability are critical. Manufactured from premium nickel-titanium alloy and processed using advanced laser micro-cutting technology, this sleeve delivers exceptional dimensional control and clean, consistent edges.

Designed for both medical and high-tech industrial environments, the micro-cut nitinol sleeve enables engineers to achieve stable performance in extremely compact systems where conventional metal tubing cannot meet design demands.

Material Properties – Micro-Cut Nitinol Alloy

This Micro-Cut Nitinol Sleeve is produced from a specialized nickel-titanium alloy known as Nitinol. The material offers two defining properties:

Superelasticity: The sleeve can endure extreme bending and deformation while instantly returning to its original shape without permanent damage.

Shape Memory Effect: After deformation, controlled heating restores the sleeve to its pre-set geometry with high repeatability.

In addition, Nitinol provides outstanding corrosion resistance, making the sleeve highly reliable in aggressive environments, including long-term exposure inside the human body.

Detailed Specifications

Inner Diameter: 0.0079 inches

Outer Diameter: 0.063 inches

Manufacturing Method: Precision laser micro-cutting

Form: Thin-wall micro sleeve / micro tube

Key Features of the Micro-Cut Nitinol Sleeve

Excellent radial strength in ultra-small dimensions

Superior fatigue resistance under cyclic loading

Clean, burr-free edges from micro-cut processing

Proven biocompatibility for medical devices

High dimensional consistency for micro-assemblies

Primary Applications

Engineers and designers rely on the Micro-Cut Nitinol Sleeve for advanced, space-constrained systems, including:

Neurovascular catheter systems

Delicate medical guidewires

Minimally invasive surgical instruments

Aerospace micro-mechanisms

Micro-robotics and advanced electronic components

In medical devices, the micro-cut finish minimizes friction and prevents snagging during navigation through sensitive anatomical pathways. In industrial settings, the precise geometry ensures perfect integration into mission-critical micro assemblies.

Manufacturing Capabilities & Quality Assurance

Our core expertise lies in micro-cut Nitinol manufacturing. We transform fine Nitinol tubing into precision-engineered sleeves using state-of-the-art CNC laser cutting systems capable of producing intricate patterns on extremely small diameters.

Following cutting, each Micro-Cut Nitinol Sleeve undergoes carefully controlled heat treatment to activate its superelastic and shape memory properties. We also provide comprehensive finishing services, including electropolishing for ultra-smooth surfaces, precision thermal shaping, and medical-grade cleaning.

Every part is subjected to strict inspection, including dimensional verification, surface quality checks, and mechanical performance evaluation. This ensures consistent quality from prototype through full-scale production.

MRI Compatibility of Micro-Cut Nitinol Sleeves

Can a Micro-Cut Nitinol Sleeve go in an MRI?

Yes. Nitinol is generally considered MRI-safe because it is not ferromagnetic. Most micro-cut nitinol components exhibit negligible movement or heating during MRI procedures.

However, final device configuration and processing conditions may influence MRI behavior. We recommend full device-level MRI testing. Our material certifications support regulatory and safety documentation.

Disadvantages of Nitinol and Our Solutions

Nitinol presents certain challenges, including higher material costs, complex machining requirements, and the need for precise stress management to avoid fatigue. Additionally, nickel content requires careful consideration for biocompatibility.

Our manufacturing expertise directly addresses these challenges. We specialize in difficult micro-cutting operations, optimize heat treatment parameters, and support design teams in leveraging the full advantages of the Micro-Cut Nitinol Sleeve while minimizing risk. For applications requiring extreme miniaturization and uncompromising performance, Nitinol remains the superior solution.

▸ Expert Guidance: 24/7 support

▸ Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

East Asia Region:nitinolwire.com

US Region:nitinolalloy.com

Mid East Region:getnitinol.com

Nitinol Wire – Superelastic and shape-memory wire for medical, industrial, and smart device applications.

Reviews

There are no reviews yet.