| Af temp | The finial temperature of factual action recovery can be tested using bending recovery method specified in ASTM F2082/F2082M-16 |

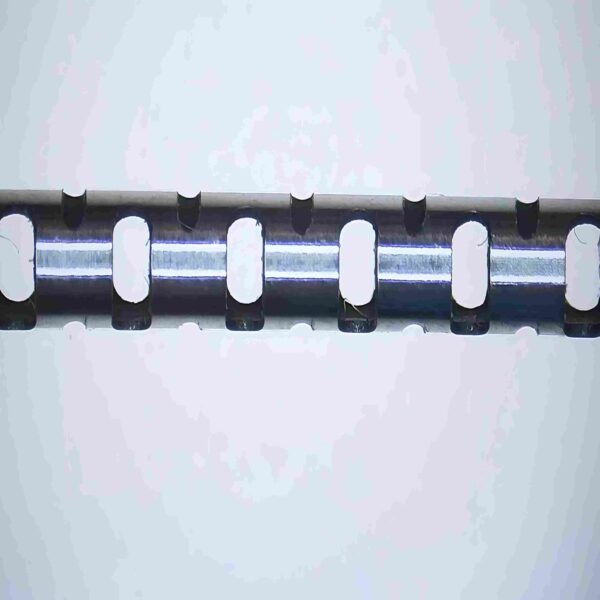

| Surface | Outer surface:oxidized state,round state Inner surface:clean state |

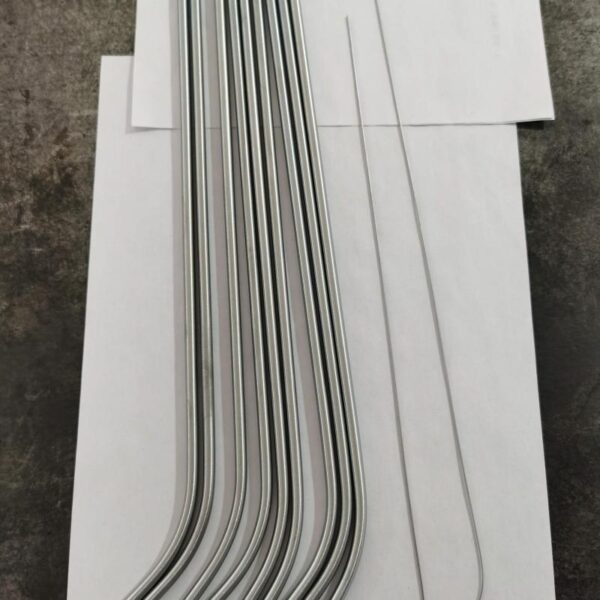

| Pipe Length | The length can be divided into precise or arbitrary lengths |

| Straightness | The requirement for straightness is negotiable |

| Surface defects | The requirements for surface defects can be negotiated |

| Applications | Medical:wave tube,camera tube,bracket,net basket,catheter |

Description

Superelastic Nitinol Memory Alloy Tube: Engineered for the Demands of Tomorrow

PRIME Project Empowers a Stronger Nitinol Supply Chain

We proudly deliver advanced nitinol memory alloy tube solutions tailored for high-performance industries. These tubes leverage the remarkable properties of Nitinol—superelasticity and shape memory—to meet the toughest mechanical and environmental challenges. From life-saving medical devices to smart actuators and aerospace systems, our tubes redefine material performance.

Our Core Material: Superelastic Nitinol Alloy

Shape Memory: The tubes returns to their original shape.

Superelasticity: The tube can bend dramatically .

Precision Tube Sizes for Every Application

Our nitinol tubes are manufactured in a wide diameter range—from ultra-fine medical sizes to large industrial formats. We ensure:

Tight dimensional tolerances

Consistent wall thickness

Smooth internal and external surfaces

This level of precision supports reliable performance in sensitive and high-stress environments.

Tailored Superelastic Nitinol Grades

Low-Af grades: Activate at or near body temperature

High-Af grades: Require higher thermal activation

Key Applications of Nitinol Memory Alloy Tube

Medical Devices:

Used in minimally invasive surgery

Core structure in stents and catheter systems

Flexible orthopedic tools

Biocompatible and fatigue-resistant inside the body

Fluid Control Systems:

High-response actuators for valve control

Leak-proof couplings for pressurized piping

Shock-absorbing tube joints

Aerospace & Defense:

Lightweight actuators for flight control

Vibration-damping elements

Thermal resilience in harsh altitudes

Robotics & Automation:

Robotic joints that flex without damage

Compact force sensors

Safe and responsive movement systems

Consumer Products:

Flexible eyeglass frames

Self-adjusting orthodontic devices

Smart actuators in home appliances

The Science Behind Shape Memory Alloys

Shape memory effect:

When cooled into the Martensite phase, the alloy is flexible and can be bent. Exposure to heat triggers a phase transformation back to Austenite, enabling the material to recover its original configuration.

Superelasticity:

Above the Austenite finish temperature (Af), applied stress causes a temporary phase shift. Once the stress is removed, the material recovers instantly—no permanent deformation.

This reversible phase transformation is the secret behind the power of nitinol memory alloy tubes.

PRIME Project: Strengthening the Future

With the launch of the PRIME Project, we reinforce our mission to deliver:

Superior quality nitinol memory alloy tubes

A robust and scalable supply chain

Tailored solutions across industries

Choose our tubes and build with confidence. Harness the strength, intelligence, and flexibility of superelastic Nitinol.

Expert Guidance: 24/7 support

Asia Region:nitinolwire.com

Middle East Region:getnitinol.com

US Region:nitinolalloy.com nitinolusa.com

Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

Reviews

There are no reviews yet.