High-performance Nitinol tubing designed for medical devices. Offers superelasticity, shape memory, and biocompatibility. Ideal for guidewires, catheters, and minimally invasive tools. Custom sizes available with fast EU shipping and certified quality.

Description

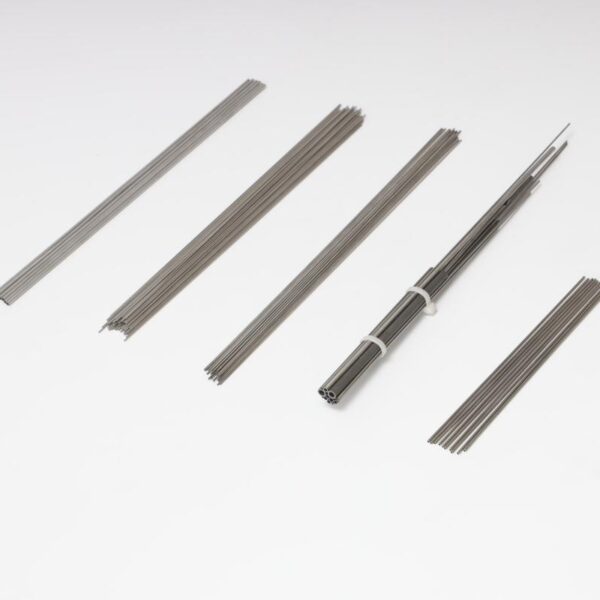

Nitinol Tubing for Medical Devices – Precision, Strength & Flexibility

Discover High-Performance Nitinol Tubing Solutions

Nitinol tubing is essential in today’s advanced medical devices, offering unmatched superelasticity, precision, and biocompatibility. Engineered for demanding clinical environments, our tubing supports a wide range of applications—from guidewires to micro implants. Whether you’re designing for vascular access, neurosurgery, or minimally invasive procedures, our tubing provides consistent and safe performance.

Why Nitinol Tubing Stands Out in Medical Use

Our tubing is made from premium superelastic nickel-titanium alloy, known for its ability to flex without permanent deformation. It instantly recovers its original shape after bending—making it ideal for navigating the human body. With excellent fatigue resistance, it withstands repeated stress inside vessels, ensuring device longevity and safety.

📎 Learn more about our Nitinol wire solutions and how they compare to our tubing offerings.

Wide Diameter Range with Tight Tolerances

We offer precision Nitinol tubing in diameters from 0.2 mm to 3.0 mm. Choose exact wall thicknesses and inner diameters to suit your application. Whether you’re building micro medical devices or robust delivery systems, we ensure tight tolerances and surface consistency with every order.

📎 Explore our custom medical Nitinol components.

Medical Applications of Our Nitinol Tubing

Guidewires: Excellent torque control, flexibility, and kink resistance

Catheters: Ideal for steerable shafts with reliable pushability

Stent Delivery Systems: Ensures smooth and accurate deployment

Endoscopic Instruments: Small-diameter tubing for flexibility and strength

Neurovascular Devices: Maintains safety in sensitive procedures

Micro Implants & Sensors: Enables medical miniaturization

Orthopedic Tools: Delivers strength and resilience in bone access devices

MIS Instruments: Facilitates minimal trauma and faster recovery

Certified Quality and Customization

We adhere to ISO 10993 and ASTM F2063 standards for biocompatibility and material quality. Our quality assurance process includes mechanical testing, dimensional verification, and full traceability.

📎 View our quality certifications

Need a custom solution? We offer tailored dimensions, special tapers, and tubing with unique mechanical properties to meet your specific device needs.

Why Partner with Us?

Superelastic & Shape-Memory Capabilities

Biocompatible, Corrosion-Resistant Alloy

High Fatigue Resistance in Dynamic Environments

Fast EU Shipping from Our German Facility

Dedicated Support from Medical Manufacturing Experts

🔗 For additional insights, visit NIH’s information on Nitinol in medical devices (external link)

Find Your Ideal Nitinol Tubing Today

Advance your medical designs with precision-engineered Nitinol tubing. Our team ensures fast communication, certified quality, and precise customization—trusted by medical manufacturers across Europe.

📎 Contact us today to discuss your project requirements.

▸ Expert Guidance: 24/7 support via nitinolmetal.com

▸ Linkedin account:Ben Xiang | LinkedIn