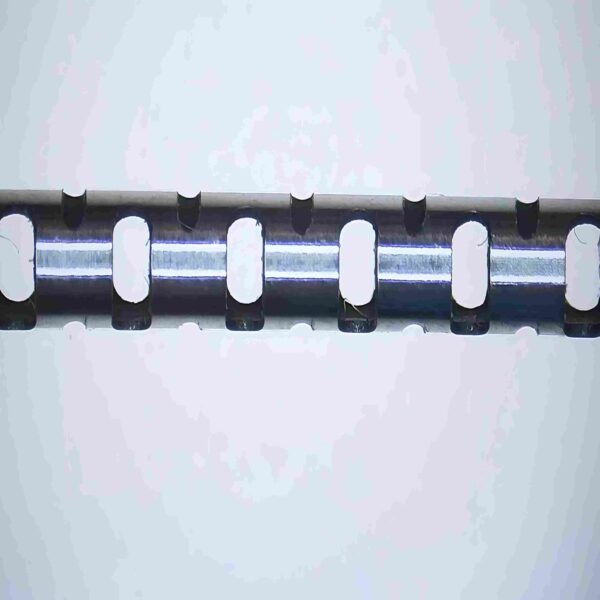

| Af temp | The finial temperature of factual action recovery can be tested using bending recovery method specified in ASTM F2082/F2082M-16 |

| Surface | Outer surface:oxidized state,round state Inner surface:clean state |

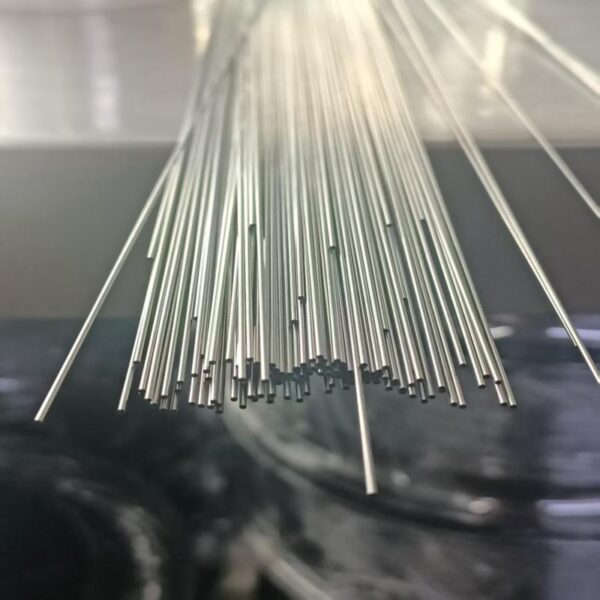

| Pipe Length | The length can be divided into precise or arbitrary lengths |

| Straightness | The requirement for straightness is negotiable |

| Surface defects | The requirements for surface defects can be negotiated |

| Applications | Medical:wave tube,camera tube,bracket,net basket,catheter |

Description

Nitinol Tube & Wire: Superelastic Solutions for Medical & Industrial Use

Premium Nitinol Products

Our factory produces high-performance nitinol tube and wire solutions. This special material offers unique properties for critical engineering and medical applications. Our products deliver reliable superelasticity and shape memory performance.

Superelastic Nitinol Material

We use medical-grade superelastic nitinol. This advanced alloy instantly recovers its original shape after bending or compression. Key grades include:

Standard SE Nitinol: Best for most superelastic needs

Fatigue-Resistant Grades: Ideal for high-cycle applications

High-Strength Variants: For demanding force requirements

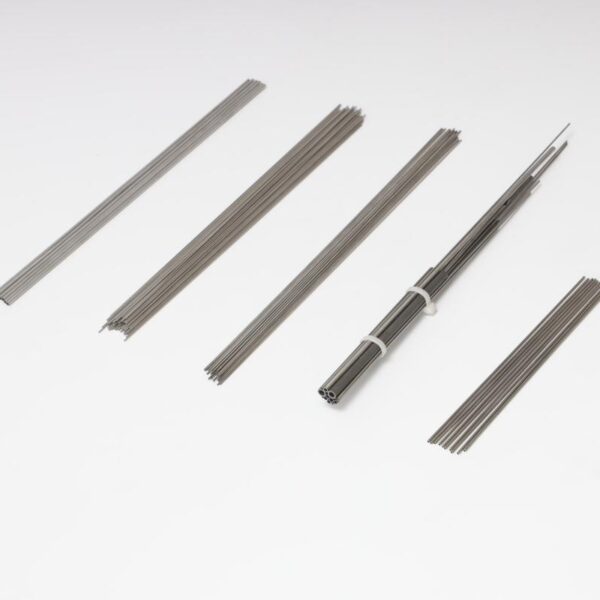

Nitinol Tube Specifications

Material: Superelastic Nitinol (ASTM F2063)

Diameter Range: 0.1mm to 25mm sizes

Wall Thickness: 0.025mm to 3mm options

Key Features: Extreme kink resistance, MRI safety, biocompatibility

Key Nitinol Tube Benefits

Superior Flexibility: Navigates complex paths without kinking

Shape Memory: Automatically returns to preset forms

Constant Force: Delivers reliable, gentle pressure

Body-Safe: Perfect for medical implants

Nitinol Tube Applications

Medical Devices: Catheters, stents, guidewires

Surgery Tools: Endoscopic and laparoscopic instruments

Industrial Systems: Corrosive fluid transfer lines

Robotics: Precision actuators and joints

Aerospace: Lightweight deployable components

Nitinol Wire Solutions

Diameter Range: 0.001mm to 6.0mm

Forms: Round, flat, or custom shapes

Key Advantages: 8% reversible strain, vibration damping

Why Choose Our Nitinol Products?

Medical-grade quality assurance

Custom sizes and processing options

Consistent superelastic performance

Reliable shape memory behavior

Global shipping availability

Nitinol in Large Engines?

Nitinol faces challenges in big power systems:

Low Efficiency: Heat engines lose significant energy

Power Density Issues: Requires impractical material volumes

Heat Transfer Limits: Difficult uniform temperature control

High Costs: Prohibitive at engine scales

Fatigue Risks: Unproven for massive cyclic loads

Expert Guidance: 24/7 support

Facebook account:Facebook

Linkedin account:Ben Xiang | LinkedIn

Reviews

There are no reviews yet.