Find reliable Nitinol strip suppliers for medical, aerospace, and industrial applications. Request samples today!

Description

Overview of Nitinol Strip

Nitinol strip is a specialized form of nickel-titanium alloy that exhibits exceptional shape memory and superelastic properties. This advanced material automatically returns to its pre-programmed shape when heated, making it invaluable for precision applications. Leading Nitinol strip suppliers offer this material in various thicknesses and tempers to meet diverse industrial needs. The unique characteristics of Nitinol strip include excellent fatigue resistance, corrosion tolerance, and biocompatibility, ensuring reliable performance in demanding environments.

Key Applications

Across Industries The medical sector extensively uses Nitinol strips for implantable devices like vascular stents and orthodontic archwires. In aerospace engineering, these strips serve as critical components in actuators, vibration dampers, and deployable structures. The automotive industry incorporates them into smart sensors and safety mechanisms. Additionally, robotics and industrial automation systems benefit from the material’s flexibility and durability. Reputable Nitinol foil providers supply customized strips tailored to specific application requirements, ensuring optimal performance in each use case.

Technical Advantages and Material Properties

Nitinol strips maintain consistent performance through millions of deformation cycles without permanent damage. They demonstrate remarkable corrosion resistance, even in harsh chemical environments or saltwater conditions. The material’s superelasticity allows for extreme bending and twisting while maintaining structural integrity. Temperature stability enables reliable operation in conditions ranging from cryogenic to high-heat settings. Leading Nitinol suppliers strip products meet stringent industry standards, including ASTM F2063 for medical-grade applications and AMS 4959 for aerospace implementations.

Product Specifications and Customization Options

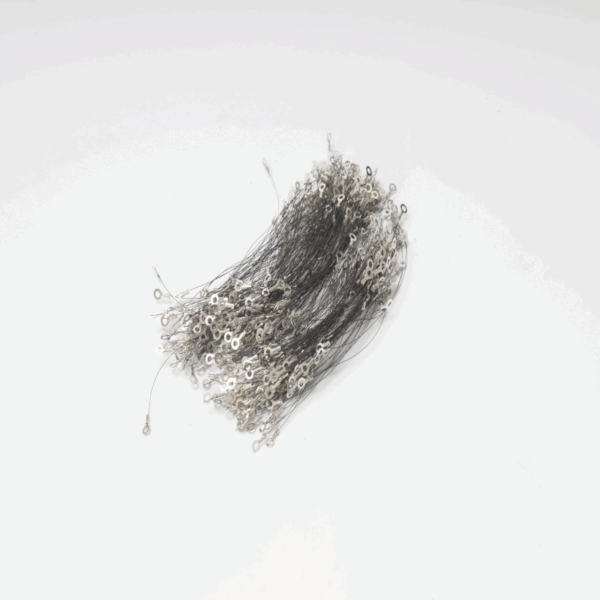

Standard Nitinol strip thicknesses range from ultra-thin 0.05mm foils to robust 2mm strips, with widths available from 1mm to 50mm. Suppliers offer both austenitic (superelastic) and martensitic (shape memory) phases to suit different functional requirements. Transformation temperatures can be precisely adjusted through specialized heat treatment processes between -20°C to 120°C. Trusted Nitinol strip suppliers provide comprehensive material certifications, including chemical composition reports, mechanical property data, and surface finish specifications. Many manufacturers offer additional services like precision laser cutting, micro-etching, and edge conditioning.

Sourcing and Procurement Considerations

When selecting a Nitinol foil provider, evaluate their material consistency, production capabilities, and quality control measures. Established suppliers maintain extensive inventory of common strip sizes while offering custom fabrication services for specialized requirements. Consider minimum order quantities, lead times, and available testing services like DSC analysis or tensile testing. Many suppliers provide free sample programs to verify material properties before committing to large orders. Global logistics networks ensure timely delivery to manufacturing facilities worldwide.

Partnering with Expert Suppliers

For technical assistance or product inquiries, contact reputable Nitinol suppliers strip with demonstrated industry experience. Request detailed quotations including material specifications, processing options, and volume pricing tiers. Leading providers offer engineering support to help optimize your design for Nitinol’s unique properties. Many maintain ISO 13485 certification for medical applications and AS9100 for aerospace components, ensuring the highest quality standards.

Reviews

There are no reviews yet.