Nitinol shape memory delivers superelasticity and precision, making it ideal for medical stents, guidewires, and advanced engineering applications.

Description

Nitinol Shape Memory: The Smart Material for Medical Devices and Beyond

Meta Description: Nitinol shape memory delivers superelasticity, precision, and reliability for medical stents, guidewires, and innovative engineering solutions.

How We Make Nitinol:

Two Metals, One Alloy:

Nickel + Titanium. Cooked together. That’s the recipe.

Melting Down:

Our team carefully charges the furnace with high‑purity nickel and titanium pieces.Fires the kiln. Melts everything into glowing liquid metal. Stirred for consistency.

The Heat Kick (Where the Magic Happens):

This part’s critical. Exact temps. Then – quench it cold. Why? This shock treatment locks in the memory.

Why It Works:

Without that heat/cold slam? Just junk metal. With it?The wire endures kinking eight times greater than surgical steel and rebounds flawlessly to its original straight shape.That’s the Nitinol edge.

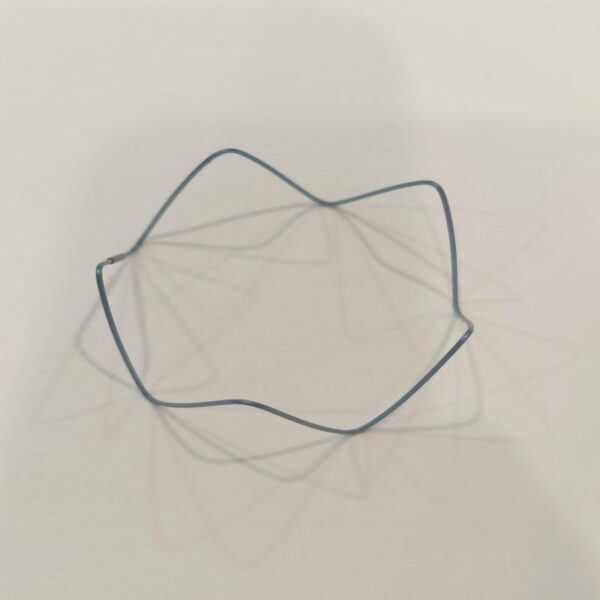

Nitinol Shape Memory & Superelasticity

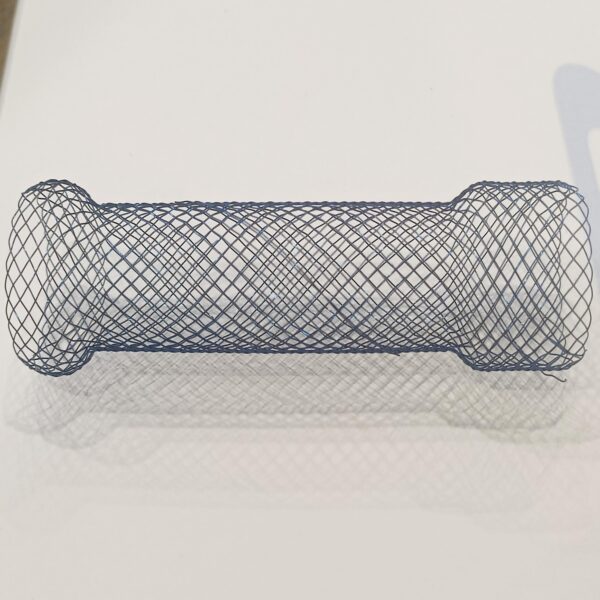

Nitinol’s shape memory enables it to recall its original shape.After deformation, it regains its initial shape once warmed, ideal for self-expanding applications in medicine.Its superelasticity means it can bend far beyond ordinary metals and spring back instantly — an essential trait for guidewires, stents, and precision medical tools.

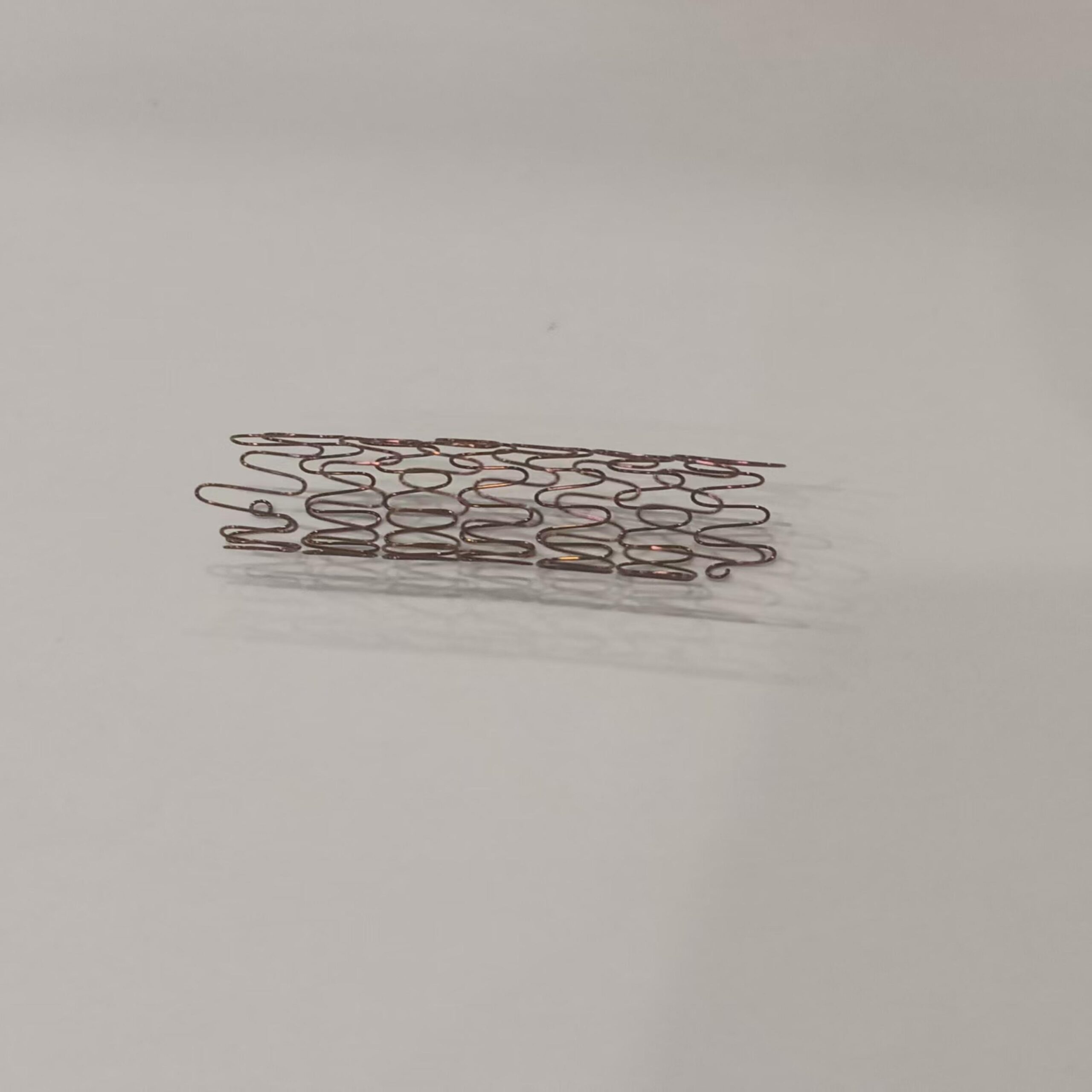

Our Nitinol Products

We provide Nitinol in various forms and specifications, ensuring a high‑quality, reliable shape memory alloy solution for stents, guidewires, and other critical applications.

Standard-grade superelastic Nitinol meets the needs of stents, guidewires, and various medical device applications.

Enhanced Fatigue Resistance: Ideal for moving parts like heart valve frames that operate in harsh, repetitive environments.

High Force Nitinol: Provides strength for load‑bearing devices like large stents or industrial springs.

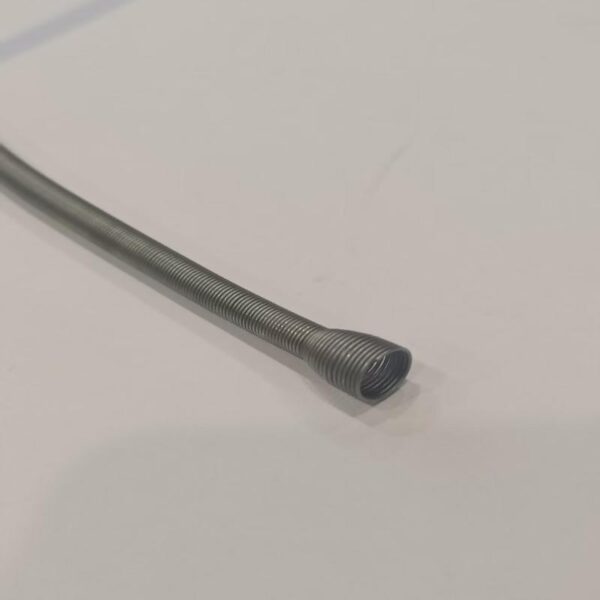

Kink‑Resistant Nitinol: Enables smooth navigation in thin wires and catheters.

Size Options for Every Application

Ultra‑Fine Nitinol Wire (0.05mm+): Enables precision in medical sensors and micro‑devices.

Standard Wire & Tube (0.1–5.0mm): Suited for stents, guidewires, orthodontics, and medical actuators.

Bars & Sheets (Up to 25mm): For large implants and structural applications.

Custom Diameters available upon request.

Key Applications of Nitinol Shape Memory

Medical Devices:

Stents: Nitinol stents expand at body inside.

Guide wire:Nitinol’s superelasticity prevents guidewire kinking, allowing for seamless catheter navigation through vessels.

Closure Devices: Enables secure, gentle vessel closures.

Orthodontics: Provides long‑lasting, precision tooth alignment.

Surgery: Enables flexible, sharp tools like biopsy forceps and root canal files.

Industrial & Consumer Uses:

Actuators & Sensors: Responsive Nitinol parts move reliably with temperature changes.

Fluid Systems: Superelastic valves maintain pressure without leakage.

Eyewear & Electronics: Enables durable, flexible frames, antennas, and micro‑switches.

Thermal Systems: Enables automatic temperature‑dependent venting or triggering.

Novel Applications: Enables responsive fabrics, toys, and engineering marvels.

Why Choose Our Nitinol?

With state‑of‑the‑art equipment and deep material expertise, we precisely control every step of Nitinol production — from alloy formulation to final heat treatment. The result is a highly dependable, precision material trusted by medical device manufacturers, aerospace firms, and consumer electronics companies alike.

Discover the Power of Nitinol Shape Memory

Thanks to its shape memory and superelastic characteristics, Nitinol delivers a reliable solution for some of the toughest engineering and medical design needs.Let us help you create next‑generation medical devices, advanced actuators, and innovative products that harness the remarkable properties of Nitinol. Contact us today to learn more!

▸ Expert Guidance: 24/7 support via nitinolmetal.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.