Description

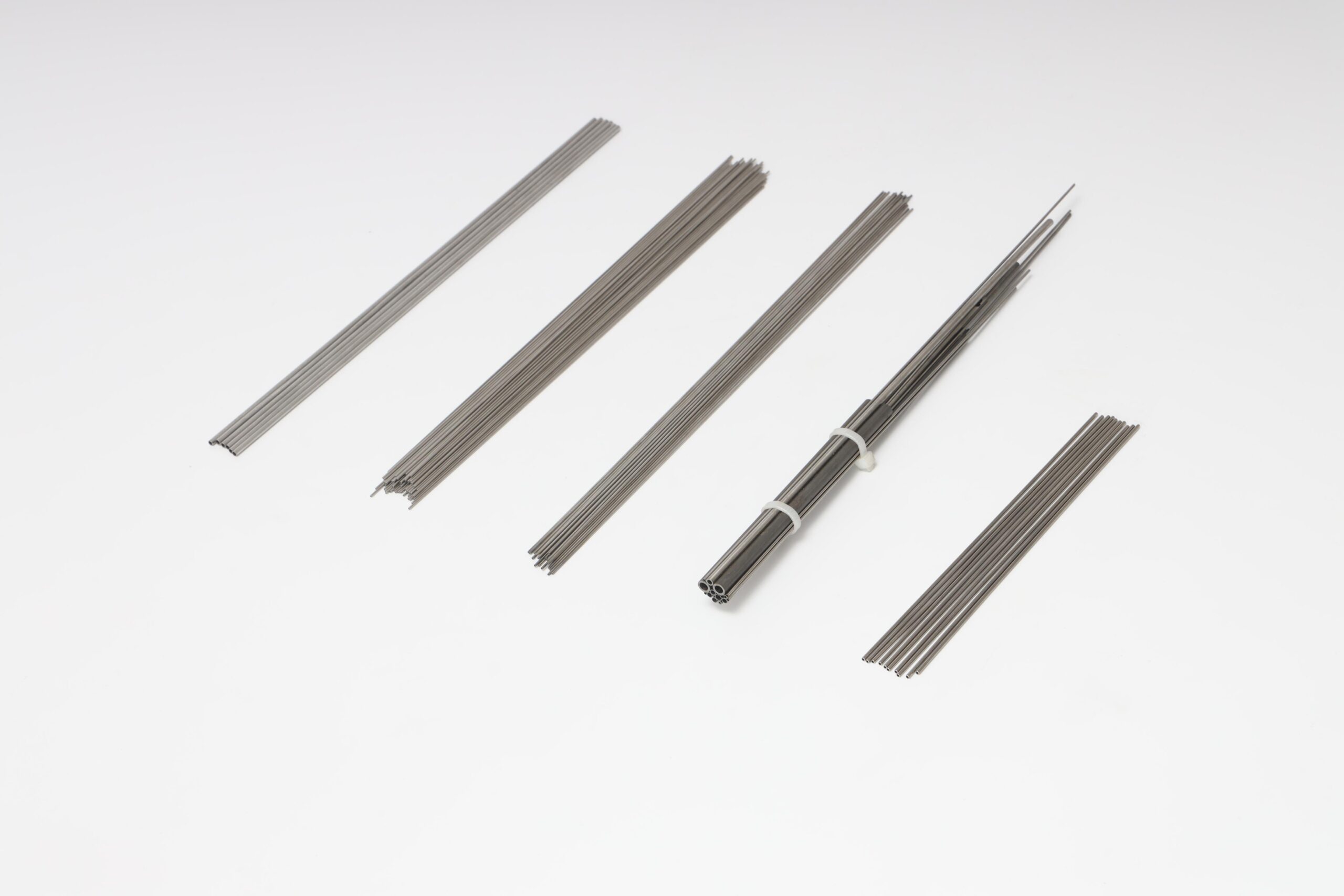

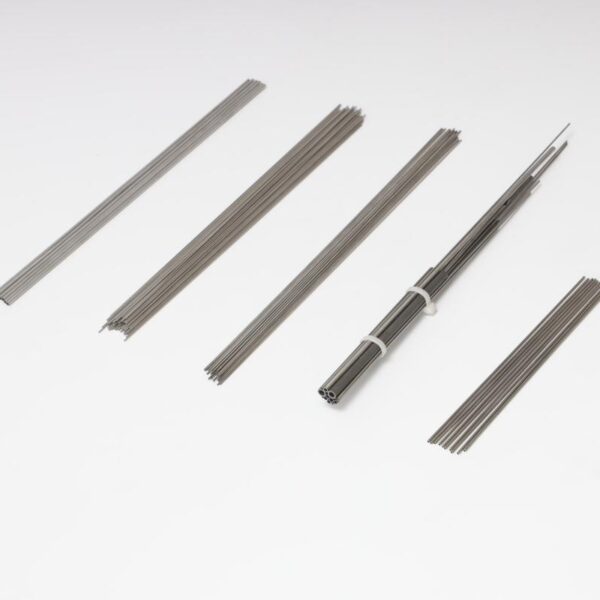

Nitinol Tube and Wire: Superelastic Materials for High-Performance Design

Discover Smart Materials with Exceptional Flexibility and Strength

We manufacture high-quality Nitinol tube and wire designed for demanding applications. Made from a premium nickel-titanium alloy, our superelastic Nitinol delivers exceptional mechanical performance, combining flexibility, shape memory, and metal strength. Replace ordinary metals with smart solutions tailored for next-generation designs.

Why Superelastic Nitinol? The Core Advantage

We specialize in superelastic Nitinol, a remarkable material that returns to its original shape after significant deformation. It acts like a metallic rubber band—bending under stress and snapping back instantly. This unique property occurs near human body temperature, making it ideal for medical and other high-performance uses. Where traditional metals fail, Nitinol tube and wire thrive.

Precision Engineering: Wide Size Range Available

We provide Nitinol wire and tubing in a full spectrum of diameters, tailored to your requirements.

Nitinol Wire: Find diameters from 0.02 mm up to 10.0 mm.

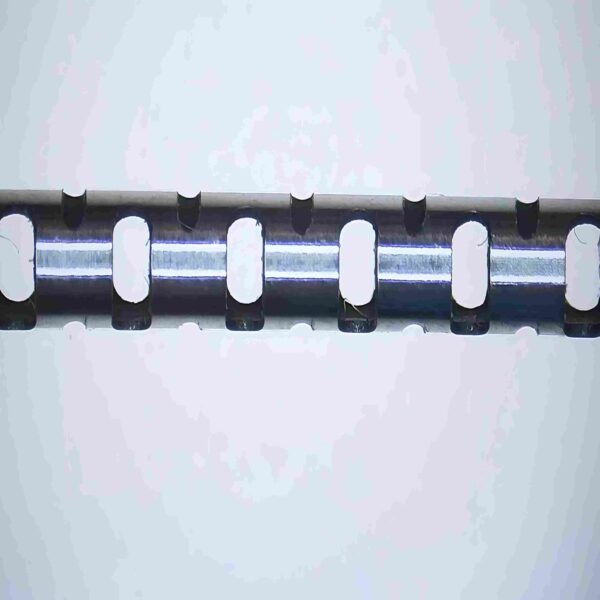

Nitinol Tubing: Micro-tubes begin at 0.05 to 10.0 mm outer diameter and we control wall thickness carefully the range is ≥ 0.05mm. We meet tight tolerances. Consistency matters for reliable performance.

Application Highlights: Where Our Nitinol Tube Excels

Medical Applications

Minimally Invasive Devices: Catheters, guidewires, and endoscopic tools rely on Nitinol for strength and flexibility.

Implants: Stents, heart valve frames, and bone fixation components use Nitinol tube for its shape memory and fatigue resistance.

Orthodontics and Surgical Tools: From memory wires to biopsy tools, Nitinol is trusted in critical healthcare applications.

Industrial and Commercial Applications

Actuators & Sensors: Nitinol responds to temperature changes, enabling precise motion control.

Durability in fluid systems is improved with Nitinol tubes used in high-precision valves, secure couplings, and vibration-tolerant fittings.

Robotics & Automation: Flexible joints and adaptive grippers benefit from its superelastic nature.

Aerospace & Energy: Nitinol components function reliably in extreme environments—ideal for satellites, dampeners, and oilfield tools.

Its superior resilience makes Nitinol a smart choice for frames, handheld devices, and high-impact sports gear.

Why Choose Our Superelastic Nitinol Products?

Outstanding superelastic behavior—tolerates large deformation and returns to its original shape unharmed.

Superior Biocompatibility: ISO 10993 certified for medical-grade applications.

Outstanding Fatigue Life: Endures millions of cycles—ideal for implants and dynamic systems.

Precision Manufacturing: Tightly controlled processes ensure consistent quality and finish.

Purity Assurance: Low impurity Nitinol with consistent transformation temperatures.

Comprehensive Testing: Includes tensile strength, surface inspection, and dimensional checks.

Custom Solutions: Get the precise diameter, composition, and surface finish your application demands.

Expert Support: Guidance from a team deeply experienced in Nitinol tube and wire applications.

Timely delivery and consistent supply ensure your project stays on schedule.

Unleash Smart Solutions with Nitinol Tube Technology

Our Nitinol products solutions enable innovation across industries. Whether you’re designing life-saving implants or cutting-edge robotics, our materials help you push boundaries and deliver superior performance.

Contact us today to find the right Nitinol tube solution for your next project. Let’s build something extraordinary—together.

▸ Expert Guidance: 24/7 support via nitinolmetal.com

▸ Facebook account:Facebook

Reviews

There are no reviews yet.